(A Practical Guide for Architects, Designers, and Facility Managers)

In the world of commercial interiors, the line between “heavy-duty wallcovering” and “wall protection” can seem blurry at first glance. Both are vinyl, both are tough, and both get specified for high-abuse areas. But once you’ve seen a busy airport corridor or a hospital back-of-house hallway five years after opening day, the difference becomes crystal clear. Here’s exactly when — and why — you should move from even the toughest Type II or Type III wallcovering to true wall protection systems.

What Wall Protection Actually Is

Wall protection (also called crash rails, bumper guards, sheet wall protection, or rigid vinyl sheet) is a category of 0.040" to 0.080" (1–2 mm) thick solid vinyl or acrylic-reinforced sheets specifically engineered for one job: to absorb impact and prevent wall damage in areas that take relentless physical punishment.

It is NOT a decorative wallcovering with a printed pattern on top (although textured and wood-grain versions exist). It is a sacrificial armor system.

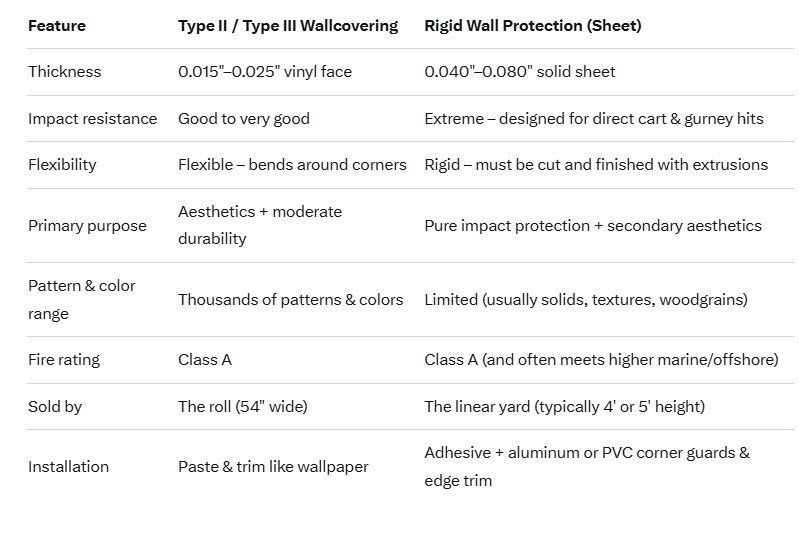

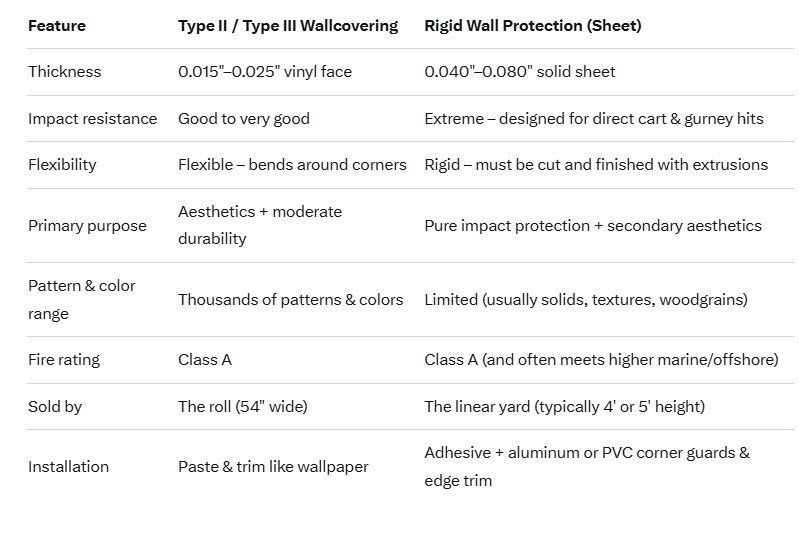

Key differences from even the heaviest Type II (20 oz) or Type III (heavy-gauge) contract wallcovering:

When You Absolutely Need Wall Protection (Not Just Wallcovering)Upgrade to rigid sheet wall protection in any area that experiences non-stop, high-velocity impact 24/7/365. Typical red-flag zones:

- Airport concourse corridors and jet-bridge waiting areas

Luggage carts, wheelchairs, strollers, and electric carts slam into walls hundreds of times per hour.

- Hotel service corridors and elevator lobbies (back-of-house)

Housekeeping carts, room-service trolleys, and luggage carts on every trip.

- Hospital main corridors, emergency department hallways, and loading docks

Gurneys, crash carts, linen carts, food trays, and portable X-ray machines hit walls at running speed during codes.

- Behavioral health and psychiatric units

Intentional impact is a real risk.

- School corridors (especially elementary and middle schools)

Kids + backpacks + running = constant collisions.

- Stadium and arena concourses

Crowds surge in and out within minutes.

- Big-box retail stockrooms and receiving areas

Pallet jacks and forklifts graze walls daily.

- Any lower 4–5 feet of wall (“wainscot height”) in the above zones

If you’re still on the fence, ask yourself one question: “Will something on wheels hit this wall at least once an hour, every hour, for the next 10–15 years?”

If the answer is yes → specify wall protection.Practical Realities of Specifying and Installing Wall Protection

- Sold by the linear yard, not the roll. Standard heights are 48" or 60" (you can also do full height in extreme cases).

- Cannot be wrapped or bent around external corners → you must use matching corner guards (usually 2" or 3" wing, 90° or bullnose).

- Inside corners and edges are finished with J-trim, division bars, or aluminum channels.

- Sheets are adhesive-applied (heavy-duty construction adhesive or manufacturer-approved contact adhesive) directly to gypsum board or CMU.

- Top edge is typically capped with a color-matched or aluminum cap trim.

- Repair is simple: a damaged section can be cut out and a new piece dropped in without replacing an entire run.

Aesthetics Haven’t Been SacrificedModern wall protection looks nothing like the institutional beige sheets of the 1980s. Today’s lines offer:

- Wood grains (oak, walnut, maple, driftwood) that are nearly indistinguishable from real wood until you knock on them

- Subtle linen and striae textures

- Over 100 standard colors plus custom matching

- Digital print capabilities for logos, donor walls, or wayfinding murals on rigid substrate

Many major healthcare and hospitality brands now use 48"–60" high wood-grain wall protection in lobbies and patient rooms because it out-performs wood, never needs refinishing, and cleans with bleach.Quick Decision Checklist

The Bottom LineType II and Type III wallcoverings are miracles of durability for 95 % of commercial projects. But when traffic never sleeps and the impacts never stop, rigid wall protection is the only product that will still look new a decade later — and save your client hundreds of thousands in repair costs.

Protect the wall, protect the budget, and sleep easy knowing the corridor you designed today won’t need a full re-skin tomorrow. That’s the real difference between wallcovering and wall protection.